O nama

2020. godine DKR je postao prvi i jedini akreditovani FANUC integrator u Bosni i Hercegovini i regionu, čime je dobio ovlaštenja da prodaje, servisira i pruža edukacije po FANUC programu, uz izdavanje važećeg FANUC-DKR certifikata.

Pored realizacije projekata automatizacije proizvodnje, pružamo mogućnosti educiranja (treniranje i re–treniranje) zaposlenika postojećih kompanija i kompanija u nastanku, srednjoškolaca, studenata i svakog individualca koji se želi usavršavati na polju automatike, robotike i CNC mašina.

O nama

Novosti

Oglas za posao – projektni inženjer/ka

Industrial Automation d.o.o. traži motivisanu, odgovornu i komunikativnu osobu za poziciju Project Engineer. Ako želiš raditi na međunarodnim projektima, sarađivati sa partnerima iz Evrope i razvijati moderna industrijska rješenja — dobrodošao/la si u naš tim!...

Trenutno otvorene prilike u DKR-u: TRAŽIMO DIGITALNOG PRODAJNOG AGENTA, REMOTE!

DKR je konstantno u potrazi za motiviranim članovima tima, zapošljavamo robot programere, plc programere, mašinske tehničare, električare…

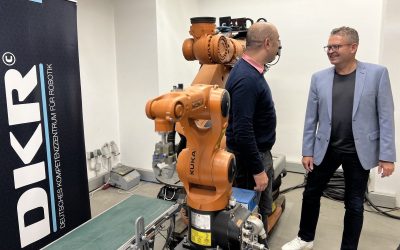

Bivši direktor KUKA AG posjetio DKR!

Dieter Hansch već 32 godine djeluje u svijetu industrijske robotike, profesionalac koji je preko 30 godina bio u samom vrhu KUKA AG, svjetskog diva i jednog od najvećih proizvođača industrijskih robota u svijetu. Upravo ovaj stručnjak posjetio je Tuzlu i DKR Centar za...

Novosti